Ridge Ventilation Systems / NFVA Formals: The Year Round Benefits of Proper Attic Ventilation

What’s the purpose of attic ventilation?

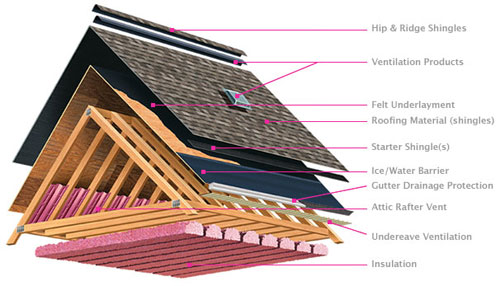

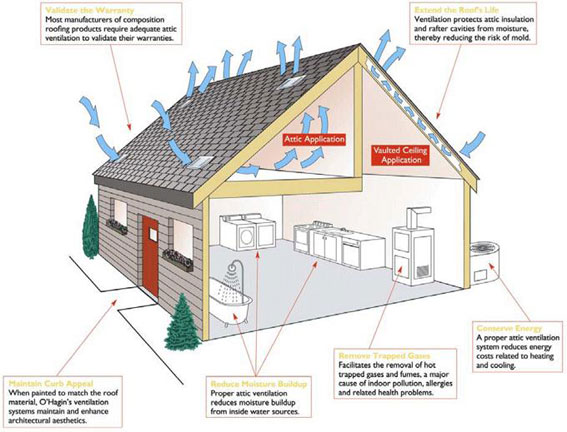

It seems like an simple question, easy enough to answer. Unfortunately, all too often, that’s not the case. Most homeowners and even some experienced builders and contractors believe the purpose of attic ventilation is to remove heat that builds up in the summer.That’s accurate, of course. But what that answer leaves out is just as important as what It includes. If you understand the principles of attic ventilation, you know an effective venting system provides year-round benefits.

- During warmer months, ventilation helps keep attics cool.

- During colder months, ventilation reduces moisture to help keep attics dry. It also helps prevent ice/dams.

- Several purposes of an attic ventilation system are to provide added comfort, to help protect against damage to materials and structure, and to help reduce energy consumption-during all our seasons of the year.

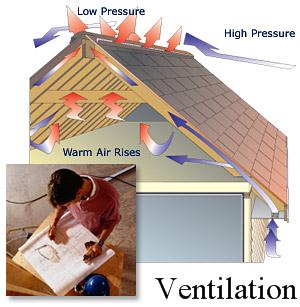

Why, on a hot day, are the upper rooms of a home always warmer? Part of the answer, of course, is simple physics: hot (lighter) air rises while cooler (denser) air falls. But in most homes – the vast majority of homes without adequate attic ventilation – a far more important factor comes into play: the downward migration of heat. Consider what happens in such a home on a typical summer day Radiant heat from the sun hits the roof. The roof temperature increases and heat travels (technically, it conducts through the roof sheathing) into the attic. As heat builds up in the attic, it radiates to the attic floor, then into adjacent living areas, raising temperatures there. You appreciate the effects of that process when you look at the temperatures involved. These are typical temperatures for a home with no attic ventilation, on a sunny day, with an outdoor temperature of 90°F (32°C).

- Temperature at roof sheath: as high as 170°F (77°C).

- Temperature at attic floor: up to 140°F (60°C).

- Temperature in rooms directly beneath attic: uncomfortable.

Dealing with the effects of moisture buildup

When winter arrives and temperatures plunge, you might think the movement of heated air would no longer cause problems in attics. But that’s not true. With seasonal changes, the conditions just reverse. Heat doesn’t travel from an attic into the living quarters. Instead, heated indoor air travels from the home into the attic – along with moisture. Furnace-warmed air circulates through the house, picking up water vapor generated by activities such as cooking, bathing, and the washing of clothes and dishes. The use of humidifiers, common in many homes, provides an abundant and continual source of moisture. Keep in mind also that the warmer the air is, the greater its capacity to hold moisture. The problem is especially acute in homes with electric heating. Most of these homes were built since the mid-1970s, using advanced insulation materials and methods. As a result, most are “tight,” allowing minimal infiltration of outside air. In addition, electric heat sources do not require air for combustion, so another common source of outdoor air has been eliminated. The positive side of these super-insulated homes is, of course, the greater energy efficiency. But because cooler, drier outdoor air is kept out, the indoor air holds greater amounts of moisture.

Ridge Vents

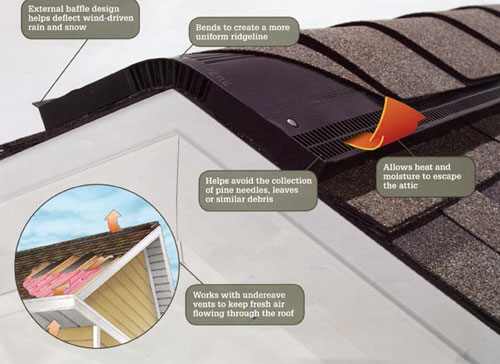

(Most Optimum) Ridge vents are a special type of fixed exhaust venting. That distinction is warranted, because ridge vents offer unique advantages when compared to other fixed venting units. Those advantages include: Maximum efficiency. The best ridge vents use an external baffle designed to draw heated air from the attic regardless of wind direction or force. When wind direction is perpendicular to the ridge, it strikes the external baffle and umps over the ridge. That movement creates a Bernoulli effect, causing low pressure to develop on both sides of the vent. When that happens, air from the attic is lifted out, in much the same way low pressure created above an airplane wing fives “lift” to the plane. The same thing happens when the wind direction is parallel to the ridge. It moves across the louvers, creating low pressure areas at the louvers on both sides of the ridge vent. In addition, when little wind force exists, ridge vents take full advantage of the thermal effect to maintain air circulation across the underside of the roof sheathing. Warm air rises to the ridge and exhausts through the vent. That allows a continuous flow of cooler air to enter through the intake vents. Only ridge vents use thermal effect efficiently and effectively, because only ridge vents provide continuous and uniform air movement along the full length of a roof.

Uniform Air Movement. Because of ridge vents run the entire length of a roof, they provide a uniform flow of air along the underside of the roof sheathing. That air movement helps eliminate “hot spots” that can develop with other types of exhaust vents—even powered vents. No other exhaust vent provides this type of airflow pattern.

Maximum visual appeal. Most ridge vents offer a low-profile design that minimizes its appearance on a roof. Shingle-over designs allow optimum blending with other roof materials.

Types of Ventilation

Static Vents: O’hagin static vents are used for both intake and exhaust ventilation. Depending on the type of roof structure, these type of vents work very well with vaulted ceilings and are an excellent choice for intake ventilation when there are not enough screened eave vents. Ohagin vents are very well respected in the roofing industry and provide 72.0 sq.in. of NFVA per unit. We inspect each home to determine specific ventilation needs and then design a system for optimum performance.

Static Vents: O’hagin static vents are used for both intake and exhaust ventilation. Depending on the type of roof structure, these type of vents work very well with vaulted ceilings and are an excellent choice for intake ventilation when there are not enough screened eave vents. Ohagin vents are very well respected in the roofing industry and provide 72.0 sq.in. of NFVA per unit. We inspect each home to determine specific ventilation needs and then design a system for optimum performance.

Power Vents: For the most part, a power fan is a motor-driven version of a wind turbine. A power fan uses the rotary motion of blades to pull air into the attic through the intake vents at the soffit and exhausts it out of the attic near the ridge. But instead of using wind power to drive the blades, power fans use electricity to drive high-efficiency motors or sunlight if they are solar powered. Unlike a wind turbine, however, the effectiveness of a power fan isn’t dependent on wind force. Instead, a power fan is turned on and off as needed, automatically, with thermostat and humidistat controls. ventilation fans Sacramento

Calculating Your Ventilation Requirements

Example: Calculating the number of lineal feet of Exhaust Vent needed for a 30’x 40’ attic:

Note: Intake ventilation MUST be at least equal to exhaust ventilation. Always have a balanced ventilation system. In no case should the amount of exhaust ventilation exceed the amount of intake ventilation.

Step 1

Calculate attic square footage

How: Multiply length of attic (in feet) times width of attic (in feet)

30’ x 40’ = 1,200 square feet

Step 2

Calculate NFA (Net Free Area) needed for this attic by using the “1 in 300” rule

How: Divide attic square footage by 300

1,200 sq. ft. ÷ 300 = 4 square feet of NFA needed

Step 3

Convert square feet of NFA to square inches

How: Multiply square feet of NFA by 144

4 sq. ft. x 144 = 576 square inches of NFA needed

Step 4

Split the amount of NFA needed equally between the intake and the exhaust

How: Divide square inches of NFA needed by 2

576 sq. in. ÷ 2 = 288 square inches of NFA needed equally for exhaust & intake

Step 5

Calculate # of lineal feet of Exhaust Vent needed

How: Divide the square inches of NFA needed at the ridge by the NFA of the Exhaust Vent

288 sq. in. ÷ 18 = 16 lineal feet of Shingle vent 2 continuous ridge vent

This attic requires seventeen (16) lineal feet of Exhaust Vent to meet FHA minimum requirements.

This is a really great post! Has lots of information, and diagrams to make it easier to understand! Keep up the good work!